5GSmartFact: addressing 5G evolution to support the future Industry4.0 – PhD student Karthik Muthineni

11/03/2025

5GSmartFact: addressing 5G evolution to support the future Industry4.0 – PhD student Karthik Muthineni

5GSmartFact is an MSCA-ITN project funded by the EU[1] whose objective is to work at the crossroads of factory automation and 5G evolution. We aim for a complete redesign of robot architectures that will lead to a leap forward in the industry automation

The project started in March 2021.

Coordinator: Josep Vidal, UPC.

Consortium

5GSmartFact features a selected consortium of academia (Universitat Politècnica de Catalunya, Aalborg University), research centres (i2Cat, CNRS: Centre National pour la Recherche Scientifique), 5G companies (NEC, Nokia, Siradel) and expert companies in factory automation (ABB, Robert Bosch, Ingeniarius, Roboception), together with supporting institutions (Universidade de Coimbra, Université Paris-Saclay).

Project website

5gsmartfact.upc.edu

https://www.linkedin.com/company/itn-5gsmartfact

PhD students

14 PhD students (early stage researchers - ESRs) were hired at the beginning of the project, with different kinds of background (robotics, telecom engineering, …) and complementary PhD projects related with wireless communications and robotics. ESR (upc.edu). 5GSmartFact ESRs spend at least half of their time working at one of the companies that make part of the 5GSmartFact consortium.

Karthik Muthineni is one of the 5GSmartFact ESRs pursuing his doctoral studies at Robert Bosch GmbH under the supervision of Dr. Alexander Artemenko and in collaboration with Universitat Politècnica de Catalunya, Spain, under the supervision of Professor Josep Vidal and Dr. Montse Najar. His research focuses on Wireless Positioning of Mobile Targets in Controlled Industrial Environments. He conducted an in-depth evaluation of wireless positioning accuracy achievable with 5G, Ultra-Wideband (UWB), and 6G Integrated Sensing and Communication (ISAC) in industrial multipath-dominant environments like industries and developed approaches for eliminating outliers in wireless signal measurements (e.g., Time of Arrival) caused by multipath effects. In addition, he developed sensor fusion approaches to enhance wireless positioning accuracy by integrating non-3GPP sensor data (e.g., Inertial Measurement Unit) from onboard mobile targets such as Automated Guided Vehicles (AGVs). All the developed approaches have been validated through simulations and industrial experiments regarding their efficiency in reducing positioning errors and reliability in real-world scenarios.

Ray-Tracing-Assisted 5G-Based Indoor Positioning in Industrial Scenario

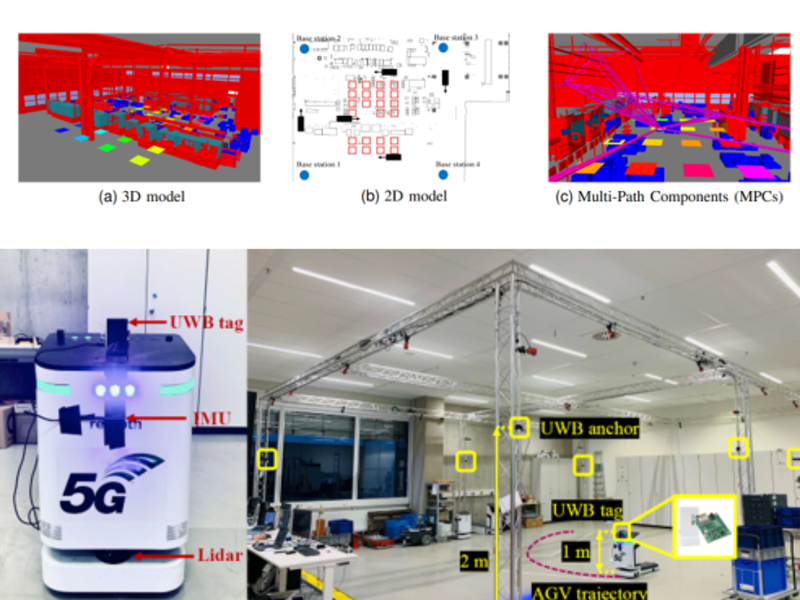

The radio channel conditions inside industrial buildings will influence the accuracy of achievable indoor positioning. Heavy metallic objects, concrete walls, and a dynamic environment in the form of moving forklifts create the Non-Line-of-Sight (NLoS) condition between the base station and the User Equipment (UE). This gives rise to Multi-Path Components (MPCs), which impede the interpretation of positional information from wireless signals, leading to errors (outliers). Position computation with outliers in the measurements can compromise the precision and accuracy requirements of the industry verticals [1]. To understand the effect of MPCs on positioning accuracy, the ray-tracing tool was used to emulate the wireless signal propagation in a highly cluttered industrial environment, which corresponds to an actual production hall of Bosch. The emulated MPCs and their respective radio signal parameters (e.g., Time of Arrival) are then given as input to the positioning algorithm, Iteratively Re-weighted Least Squares (IRLS) implemented by Karthik. The algorithm then identifies and rejects the measurements contributing to the outliers. The efficiency of IRLS in identifying and rejecting outliers was validated in 5G frequency bands, including C-band and mmWave-band. Moreover, the achievable positioning accuracy with 5G under C-band and mmWave-band inside an indoor industrial environment was derived [2].

Figure 1: The 3D and 2D models of the industrial environment. The MPCs emulated by ray-tracing engine between the base station and receiver.

Fusing Ultra-Wideband and Inertial Measurement Unit Data for Enhanced Positioning Accuracy of Target in Industrial Scenario

Wireless signal propagation in challenging environments like industries is complex due to frequent NLoS/multipath conditions. In addition, the AGVs can find themselves in blind spots of industry, where there is poor reception of wireless signals, affecting the accuracy of wireless positioning. To overcome such situations, additional information obtained from the inertial sensors of the AGV, which is not affected by NLoS/multipath conditions, can be used for positioning. To this end, Karthik explored and implemented several sensor fusion approaches based on Deep Neural Network (DNN), Long Short-Term Memory Network (LSTM), and Extended Kalman Filter (EKF) for fusing the wireless measurements from the UWB with inertial sensors onboard the AGV to obtain enhanced position estimate of the AGV. Karthik validated all algorithms through real-world experiments in the industrial laboratory of Bosch.

Figure 2: Automated Guided Vehicle with UWB, IMU, and LiDAR sensors (left). The experimental scenario (industrial laboratory of Bosch) with deployed UWB infrastructure (right) for validating the performance of DNN, LSTM, and EKF positioning solutions.

Figure 3: Considered trajectory of AGV for collecting measurement data from the sensors (UWB, IMU, LiDAR) to train DNN and LSTM.

Graph Neural Network-Based Data Fusion and Positioning in Industrial Scenario

To solve the problem of traditional DNNs adapting to input changes during runtime, Karthik explored a graph-based solution known as Graph Neural Network (GNN) for target positioning. For instance, the AGV traversing in the industry receives positional information from wireless transmitters that differ from location to location. As a result, the DNN or LSTM trained on the input features from a specific number of wireless transmitters might not perform well when the number of input features received during the testing phase does not match the training phase. Therefore, Karthik developed a positioning solution based on GNNs that can adapt to the input changes and effectively fuse UWB and IMU measurements to estimate the target AGV's position. Karthik validated his solution through real-world experiments at ARENA2036 Research Campus, Germany [3].

Figure 4: Positioning of target AGV in real-world industrial environment of ARENA2036, Germany using Graph Neural Network.

Secondments

During his PhD, Karthik completed secondments at i2CAT (3 months) and UPC (3 months). The secondment of Karthik at I2CAT was carried out under the supervision of Dr. Marisa Catalan and Professor Josep Paradells. The focus of his secondment was to build the testbed of UWB for positioning tasks and to explore different sensor fusion approaches. The secondment of Karthik at UPC was carried out under the supervision of Professor Josep Vidal and Dr. Montse Najar. His secondment focused on developing GNN-based data fusion and positioning solutions.

To know more:

[1] K. Muthineni, A. Artemenko, J. Vidal and M. Nájar, "A Survey of 5G-Based Positioning for Industry 4.0: State of the Art and Enhanced Techniques," 2023 Joint European Conference on Networks and Communications & 6G Summit (EuCNC/6G Summit), Gothenburg, Sweden, 2023, pp. 120-125, doi: 10.1109/EuCNC/6GSummit58263.2023.10188352.

[2] K. Muthineni, A. Artemenko, J. Vidal and M. Nájar, "Outlier Rejection for 5G-Based Indoor Positioning in Ray-Tracing-Enabled Industrial Scenario," ICC 2024 - IEEE International Conference on Communications, Denver, CO, USA, 2024, pp. 5081-5085, doi: 10.1109/ICC51166.2024.10622520.

[3] ARENA2036, The Research Campus, https://arena2036.de/en/

[1] This Project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 956670

Comparteix: